America’s solar manufacturing renaissance is bringing back vital jobs and dollars to rural northwestern Pennsylvania

Deep in the heart of northwestern Pennsylvania, amidst the farmland, sugar maple trees and sprawling Appalachian Plateau, an economic revival is taking place. After years of struggling to recover from a prolonged slump, remote Crawford County is receiving a much-needed economic shot-in-the-arm thanks to a unique agreement that’s creating high-tech manufacturing jobs and pumping money into the local economy.

Like many rural regions across America,

Crawford County was devastated by the Covid-19 pandemic and the economic

downturn it triggered. Hundreds of workers were put out on the street and

families were shaken when a paper plant that was the county’s largest employer closed

its doors.

Among the businesses hit hardest by the recession was a factory that produced glass for the automotive market. The Vitro

Architectural Glass plant was an instrumental part of the local economy—providing

crucial jobs, supporting numerous supplier companies, and sustaining merchants

throughout the community. Much of that was wiped away when the plant’s production

Line 2 was shut down in 2020.

Now, jobs and dollars are returning to Crawford

County, sparked by a partnership that’s not only giving a second life to the

closed production line but also adapting it for an emerging technology market.

Through an agreement with First Solar, Inc.—the largest solar technology and

manufacturing company headquartered in the United States—Vitro is rebuilding

Line 2 at its Crawford County plant to produce high-tech glass for use in solar

panels.

"They went from shutting down half

of their plant due to lack of work, and it looked like it was just a matter of

time before they closed completely,” said Greenwood Township Supervisor Kurt

Dennis. “Then all of a sudden, they announced that they were going to be

bringing the second line in their plant back online and hiring another hundred

or so workers back. It's obviously a big plus for our community."

The agreement between First

Solar and Vitro is beneficial

to both companies. It also delivers some far-reaching benefits that could

provide a substantial jolt to small town economic development across Crawford

County.

A major overhaul

The Vitro glass factory sits on the edge of Greenwood Township, which is a 20-minute drive south of the county seat in Meadville and home to about 1,400 residents. When it was dedicated in 1970 by PPG Industries (the original owner), the facility was considered one of the world’s largest float-glass plants of the time.

Fifty years later and nearing the end of its productive life, the factory’s Line 2 was forced to shut down in 2020. A combination of dropping demand for US-made automotive glass, oversupply in the automotive glass market driven by state-subsidized Chinese manufacturers, and the COVID-19 pandemic made it difficult to justify the substantial investment needed to update the facility.

However, the 2023 agreement with First

Solar allowed Vitro to upgrade and modernize the factory to support advanced

technologies in the rapidly growing solar industry. Line 2 is now undergoing a

complete transformation to realign it for manufacturing float glass for solar

modules.

A major factory expansion that’s

underway will create an [annex/wing] where workers will perform finishing processes

to prepare glass plates for assembly into solar modules in one of First Solar’s

vertically integrated solar manufacturing facilities. The centerpiece of the rebuilt

line is a brand-new float furnace that’s being constructed on-site.

“There’s going to be a lot of other offline stuff going on, like tempering ovens, so we will be doing additional work after we make the glass,” said John Becker, Vitro furnace operator. “We're just happy that the furnace is being rebuilt, and we have these opportunities coming to us.”

To serve newly created demand for high-quality float glass from First Solar, Vitro initially announced a $93.6 million investment to overhaul Line 2 and subsequently increased its investment to approximately $180 million to include a second facility in Carlisle, Pennsylvania. Carlisle is located about 270 miles southeast of Meadville in rural Cumberland County and its reconfigured production line is also expected to provide a boost to the local economy when it comes back online during the second half of 2025.

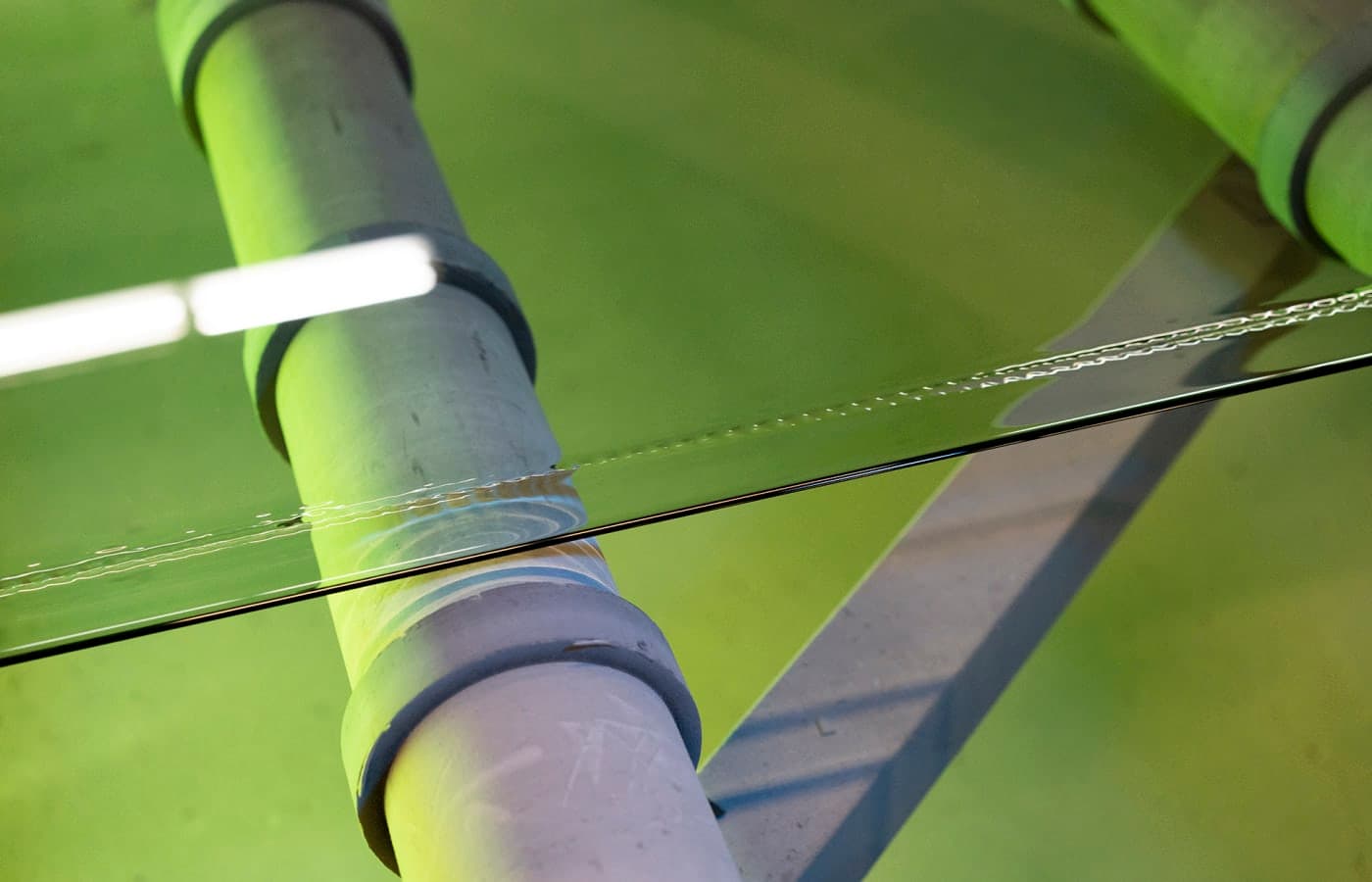

The two Pennsylvania facilities won’t produce ordinary float glass but rather a high-performance superstrate for solar modules. This is the specialized glass that sunlight passes through to reach a layer of thin film semiconductor (just three percent the thickness of a human hair), where photons are converted into electrons. In 2023, Vitro was awarded a $1.6 million grant under the US Department of Energy’s Solar Manufacturing Incubator program to develop this high-tech glass product at its research and development facility in Cheswick, Pennsylvania.

In Crawford County, it’s a story of not just rebuilding a factory, but rebuilding a work force to succeed in a new industry.

“My father retired from the plant after 38 years, it's always been great for jobs in the community, so this is incredible to be able to add more jobs,” said Darrin Overton, Vitro batch house engineer. “We shut down Line 2 – half of the plant – when Covid hit and nobody in the world knew what was coming next. Vitro found us this great opportunity to get into this new area making glass for solar panels.”

Vitro has already begun hiring new workers for the rebuilt Line 2. When the facility becomes operational in 2025, approximately 130 new permanent jobs will have been created. Those workers will join thousands of American solar workers in enabling the US energy transition.

“It's a significant private sector investment for Vitro to make in Crawford County and one of the largest manufacturing investments in the county for at least the last decade,” said James Becker, Executive Director, Economic Progress Alliance of Crawford County. “Job creation is always a plus, and these are strong, family-sustaining, quality benefits-package positions and it's truly a plus for the county and the local economy.”

Investing in America

Investing in American manufacturing allows First Solar to respond to the growing market need for solar in the United States with domestically manufactured products.

Unlike Chinese solar manufacturers that are setting up facilities across the United States to assemble solar panels with imported components (including glass), First Solar operates what is believed to be the industry’s most extensive domestic supply chain. For instance, the Arizona-headquartered manufacturer is one of the single largest consumers of US-made float glass, accounting for approximately 15% of the country’s total capacity.

This reliance on American materials to make American solar panels helps support the country’s energy independence—with solar technology made in America, for America.

"It's exciting to see, and it's certainly an asset for that portion of the county as well as the northern portion of Mercer County, our neighbors to the south,” said Crawford County Commissioner Chris Seeley. “The whole area is affected by the employment at that facility.”

The economic impact of a factory revitalization such as the Vitro upgrade includes capital investment, more jobs for skilled workers, and support for suppliers. Widespread benefits are felt as money circulates through the community. Increased tax revenues translate into funds for schools, roads, public safety, and additional community infrastructure.

“The population in this area has been declining slowly,” said Linda Murdock - Greenwood resident. “I'm glad they’re going to hire people at the plant. It will be a much higher tax base for the township, which is great.”

The agreement at the heart of the small-town revitalization in Crawford County was catalyzed by the Inflation Reduction Act of 2022, which set in motion a renaissance in American solar manufacturing. First Solar has manufactured in the US since 2002 and had already invested in three Ohio factories prior to the Act being signed into law. Following its passage, First Solar announced plans to build two new factories in Alabama and Louisiana, each representing a $1.1 billion investment and approximately 800 new manufacturing jobs. The Alabama facility was commissioned in September 2024; the Louisiana facility is expected to begin commercial operations in the second half of 2025.

As First Solar expanded, so too did its need for domestically made glass, and while it already sources float glass from plants in Illinois, Michigan, and Ohio, Vitro’s ability to rapidly revamp and recommission the Crawford County facility made it an attractive addition to the solar manufacturer’s US supply chain.

In addition to direct employment, the factory will support numerous contractors and suppliers.

“It's good to see a local company expanding because in the long term we will also benefit and be able to grow as well,” said Clint Snyder, project manager/estimator with Overhead Door Company in Franklin, Pennsylvania. “It creates a local economy that stimulates work.”

“This second line means more local work for us, so we don't have to drive out of town and pay for gas and a hotel out of pocket,” said Todd Kleist, who works for Vitro contractor Wm. T. Spaeder. “That all costs us money so it's good to be able to work locally.”

The economic benefits generated by the reopened factory line are expected to have a ripple effect as the influx of jobs for skilled workers earning good wages pours money into local businesses—the restaurants, boutiques, bookkeepers, barbers, bakeries and other shops and services supported by those workers’ paychecks.

“Having new jobs added is a good thing for the community,” said Renee Rice, owner of Countyline Café in Hadley, Pennsylvania. “Eventually the benefit flows through to businesses like ours.”

The resurgence that’s taking place in Crawford County provides an excellent example of First Solar’s economic impact on a community level.* Viewed from a broader perspective, the scope of that impact appears substantial. The company’s annual operational impacts on the US economy are projected to grow to a total of more than 30,000 direct, indirect and induced jobs and almost $2.8 billion in labor income by 2026, when the company expects to have over 14 gigawatts of US manufacturing capacity. Operating at that scale will support nearly $5 billion in value added and over $10 billion in output to the US economy including direct, indirect, and induced economic effects.

That’s a huge boon for communities with economies in need of a jumpstart.

*Data and information generated by an economic study commissioned by First Solar and conducted by the Kathleen Babineaux Blanco Public Policy Center at the University of Louisiana at Lafayette. The economic study is based on numerous assumptions, estimates and other data as more fully described in the report summarizing the study’s findings, which is available at www.firstsolar.com/USeconomy.

High-Tech Transition

What’s happening in Crawford County

isn’t just about bringing jobs back to the region—it’s about bringing in

good-paying, high-tech manufacturing careers. The manufacturing agreement with

First Solar enables Vitro to transition from dependence on the automotive

industry, where demand typically fluctuates, to an emerging technology sector

with steadily growing demand projected.

\

“The expansion brings work back into the area that we had lost during Covid. There's a lot of people here that we know, friends and family in the community that are going to benefit from this coming back,” said Brian Campbell, service manager for Arrow Electric in Greenville, Pennsylvania. “The growth of Vitro will help us grow and solar is the next generation of energy that I feel is going to be around for a long time.”

As it transitions into the emerging PV glass market, Vitro expects to grow. The upgraded factory in Crawford County is projected to more than double the current output at Vitro, which anticipates generating approximately $1.3 billion in sales over the next decade as a result.

American-Made

Northwestern Pennsylvania joins factories in other regions that are benefitting from First Solar’s $4 billion investment in American solar manufacturing. But true value is being created for the United States that extends well beyond the direct investment and creation of jobs in factories producing solar modules.

As solar becomes a more popular option, it’s awesome to see panels manufactured and produced right here in America, here in Pennsylvania, so that we can continue to power our energy needs internally here domestically,” said Pennsylvania State Representative Thomas Kutz, who represents the 87th legislative district in Cumberland County. “So, they have American workers making American products to power America’s energy and reduce reliance on foreign energy sources, which is exceptional.”

First Solar embraces a philosophy of Responsible Solar that emphasizes sustainability and responsibility in all aspects of its business. The company has a long history of establishing benchmarks in solar panel recycling, supply chain transparency, the carbon and water footprint of its technology, and health and safety.

“It's good for jobs, it's good for the economy and it's good for the environment,” said Meadville Mayor Jaime Kinder. “And solar is an energy that isn't taking more from us than it is giving. I want this community to be a place where my grandbabies can be, where they can live and find their joy.”

Careers for the next generation

“This means a lot to the small towns in this county,” said Coleen Mikovich, Vitro mobile equipment operator. “It’s job security, employment, and a future. There are people here that have had generations of workers here. I mean we’re kind of like coal miners here, where generation after generation of families work in this glass plant.”

When the Vitro factory renovation is completed and PV glass for First Solar modules starts rolling off Line 2, it will signal the beginning of a new era in a long tradition of Crawford County workers manufacturing American-made glass for American products.

“My daughter works here so she’s the third generation at the plant,” said Chris Gallagher, Vitro maintenance mechanic. “She works in accounting and my dad used to be an operator on the floor.”

By making the transition to manufacturing glass for a renewable technology in an emerging industry with steadily growing demand, the remodeled Vitro plant could have a long-term impact on the economy – and the people – of Crawford County.

“There's going to be a lot of opportunities for the next generation,” said James Hart, Vitro packing operator.